It’s often that we only see the surface of what Scotland’s technology industry has to offer. This is especially true of the Enabling Technology sector, which boasts 10% of Scotland’s exports. Shining a light on the semiconductor industry, we caught up with Tim Kerby, CEO of Edinburgh Systems, to find out more about the industry, the importance of understanding customer requirements and systems thinking.

Read [Interview - Part 1] Systems Engineering - Tim Kerby

Background

Edinburgh Systems was founded last year as a consultancy targeting businesses looking to develop into safety and security markets. We enable firms to develop complex and robust products by introducing them to leading engineering practices from across industry and tailoring them for the semiconductor and technology sector. Our primary focus is in systems engineering and product management techniques.

Industry Overview

Over the last few years, we’ve seen a major shift towards functionally safe products in the semiconductor industry. The primary drivers of this shift are the growing automotive and medical markets, however traditional market areas such as industrial are also demanding functionally safe products as complexity and functionality of semiconductor devices increases. In addition to safety, product security has become a challenge as IoT has brought internet connectivity to many devices. Both safety and security require new rigorous methodologies for design that are often unfamiliar to semiconductor teams. As a company, we strive to improve capability in these areas and help companies develop to standards, such as ISO26262 and IEC61508.

We also spend time working outside of semiconductor because the systems approach we use, particularly systems thinking techniques, apply widely including in financial services, healthcare and other areas. This is very important to us as it allows us to continually learn and bring in best practices from other disciplines.

What is a Systems Engineer?

Over the years, I’ve seen many people being called a “Systems Engineer” because they happen to work on systems, but it’s an engineering discipline in its own right. A Systems Engineer’s role combines three things: ability as a leader, the technical knowledge in the field you’re working in, and the ability to understand systems thinking.

Systems thinking is very problem focused; it’s about looking at the big picture and not just low-level detail. You have to consider the system from different perspectives; looking at its boundaries and how it interfaces to and performs with other components.

A systems thinker will first want to find the right problems to solve. They will work mainly in the problem-space, analysing and refining requirements to ensure they have value and are pervasive in the market. When they come to propose and evaluate solutions, they will see the bigger picture and look to optimise each component for the best performance as part of a system. That often means taking different decisions than an engineer would have done if they were designing a component in isolation. This often means collaborating across disciplines and even companies.

As an example, if a semiconductor company was developing a photodiode for a LIDAR system, they would look to work with the laser manufacturer and optics designer for the system to get the best-matched performance. Someone on the team would also go beyond this and look at the bigger picture such as where the sensor was positioned on the car, how the weather influenced performance and what safety measures needed to be in each component to make sure the system was eye safe. No one component can be designed in isolation.

The best systems engineers are good facilitators. They know enough about all the disciplines to understand and evaluate decisions, but they leave the design up to the experts who have a better understanding of the detail. They are often considered to be “expert generalists” or “versatilists”.

Why aren’t all engineers Systems Thinkers?

I’ve found that we don’t tend to teach systems thinking in the education system, either at schools or universities and this means companies often have to retrain engineers how to think when they are recruited as graduates. The engineers may have the technical knowledge to solve challenging problems and the creativity to innovate, but it doesn’t help if they don’t understand how to identify the right problems to solve. That ultimately means that they can be building the wrong product for the market.

As educators, parents and mentors we can do more to build systems thinking. Think of a child playing with Lego; they will use their creativity to build and innovate but how often do parents or teachers encourage them to think about what they want to build and why they are building it before they let loose with the bricks? Asking simple questions like ‘who is the castle for?’, ‘how big should it be to fit Barbie inside?’, and ‘what will she do in the castle?’ teach children how to apply systems thinking and understand how they can use their creativity to solve bounded problems. As we progress through the education system, we are taught the technical knowledge needed to succeed in our careers; however, it’s rare to see schools or universities developing the skills in requirements elicitation and systems thinking needed in industry. There are opportunities to include this in project and teamwork that are often missed.

What does a Systems Engineer do?

At the core, systems engineering is a technical facilitation role; we use information to find the best solution to problems and make technical trade-offs in design such as whether a function is best accomplished in hardware or software.

Considering whole-system performance is key and engineers can no longer look at their own component in isolation. For example, if you have an electric vehicle, like a Tesla, and the battery team optimised for the largest range without constraints, they would end up building a battery which was so big and so heavy that it may not fit into the body or the weight would slow the car down. For the best overall performance of the vehicle, the teams need to work together and collaborate on a common goal, rather than optimise their individual components. It’s one of the roles of the Systems Engineer to manage this process.

Why do we need Systems Engineering?

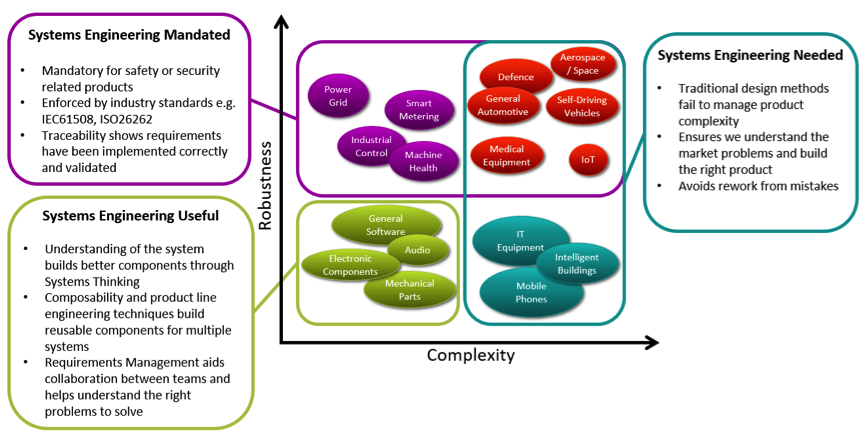

Systems engineering is of most benefit as the complexity and robustness of products increases. This is a trend we see as more products are sold into lucrative safety critical markets and more intelligence is built into individual electronic components.

Considering increasing complexity, the traditional methods engineers use to manage information fail. Emails and presentations are not version controlled. Teams are larger and spread geographically so they find collaboration harder. It becomes more difficult to understand the impact of change and how that propagates through the system. Individuals hold undocumented knowledge and teams can’t see the bigger picture. These challenges result in errors in development, costly respins and potentially late entry to the market.

Increased robustness is a requirement for both safety and security. We must have the ability to analyse where faults may occur in the system and take actions to mitigate against them. This may be the failure of a component involved in your car’s braking system or the security of your home security cameras. Industry standards now dictate a systems approach such as ISO 26262 for automotive development. A formal record that traces the decomposition of the design into components and their verification and validation is needed to ensure the design is safe and protect both end users from harm and companies from liability.

Why do products fail?

Typically there are two things that cause a product to fail. The first is where companies build the wrong product. This may be because they lose track of what their customers need, don’t understand the market problems or focus solely on innovation led design where people internal to the company put their own desires to innovate above the market needs. The second cause is where companies build the product wrong. Their engineering methods fail and they have to rework the product. We often see this breaks down where different teams have to interface for instance a control signal being active high versus active low.

While companies are busy reworking products as they don’t meet market needs or they have bugs, the market has moved on, the customer has found someone else or they find the product costs too much to build to make a profit. As the complexity and integration of products increases, less products are released to market each year and that makes it far more important that they are the right product.

Systems engineering is about doing enough work up front to understand what you need to build that when you come to build it, you get it right first time. This prework not rework approach minimises the costs of design change as change is managed early in a project before the cost of change increases (e.g. when wafers have been manufactured).

Where do companies need support?

Introducing a systems approach is difficult and often requires changing the distinctive competence of a company to move from producing semiconductors to producing systems. Change is not easy, particularly when there has been a long successful history of building high quality electronic components with traditional methods.

We find the key issue is building a critical mass of internal capability that is sufficient for the company to continue to learn and support themselves. That’s where we usually step in, taking a strategic role in the organisation to develop the capability and also deliver immediate resource to the engineering teams.

Most companies we work with have no Systems Engineers or perhaps a few responsible for the Functional Safety of products. This makes introducing the tools, processes and methodologies more of a challenge than, for instance, bringing on board a new electronics design tool. We don’t have the experienced engineers with the understanding they need to lead their teams along the right path and coach and mentor others. By running incubator projects and stepping in to provide the capability in the short term, we provide the company with the leadership and the breathing space to develop. This allows us to hand over the sustaining activities to an experienced internal team within one to two years from the start of an engagement.

What other related challenges do you see?

Many organisations are looking to move towards a more market-led approach to development and fit in exceptionally well with requirements management and systems engineering. We often see that marketing staff are focussed solely on outbound promotion of products rather than being trained to elicit problems from the market and understand their value. It’s hard for marketing and sales to get the right exposure the engineers who can express these problems and it may need a different team who visit customers solely to carry out these product management activities and represent the voice of the customer back to design teams. Having a good understanding of the market is critical to building the right product and that means considering many more stakeholders than existing customers. You can often learn as much from why people aren’t buying your products or by talking to end users than you can from your existing clients.

We see recruitment as another challenge as companies often have difficulty specifying the new roles that they need to develop complex and robust products. In addition to systems engineers, we see many projects requiring software engineers, functional safety managers, networking engineers and security specialists to name a few. Without already having a core of staff in these areas, understanding the type of person needed and identifying qualified candidates can be very difficult. What often happens is companies recruit people who look closest to existing staff and we’ve often seen roles advertised for software engineers with experience of transistor-level design for example. This often results in companies missing out on the best candidates.

We’ve used our experience to write job descriptions and help companies recruit and we would recommend working with technology recruiters who really understand product design, such as Enigma People Solutions. Enigma is able to learn about the company and its needs, and then find the right person who can solve a problem for them. It’s rare to find a recruitment company that will go full circle like that at the moment.

What advice would you give to companies in this area?

Companies shouldn’t be afraid to embrace change and as we see the pace of technological innovation, it’s necessary to embrace this change to compete.

Ensure you allocate some strategic budget to improve how you carry out your engineering in addition to budgeting for the innovation that drives your product developments. Finding a good services partner to guide you on this journey is an investment for the future that can have substantial returns for your organisation.

Read [Interview - Part 1] Systems Engineering - Tim Kerby

Enigma People Solutions is an award-winning technology recruitment consultancy. We find technical leaders for the emerging and enabling technology industries. Visit our job search page for the latest vacancies in photonics, electronics, semiconductor, software and IoT in Scotland. Check out our blog for the latest in the technology industry. You can get in touch with us hello@enigmapeople.com or call us on + 44 131 510 8150